- Home

- Products

- Pipe / Tube Forming Machine

- Spiral Filter Core Forming Machine

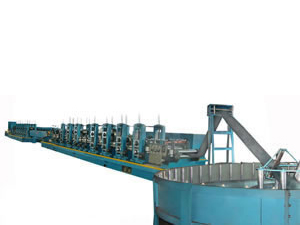

ZHL-150 Spiral Filter Core Forming Machine

Description of ZHL-150 Spiral Filter Core Forming Machine:

This forming machine is especially suitable for producing spiral steel core for automotive filters.

Features of ZHL-150 Spiral Filter Core Forming Machine:

1) The diameter of spiral tube can be changed easily and quickly.

2) Any length can be cut according to customer's requirement.

3) By adjusting clutch, the spiral forming machine can be suitable for materials of different thick.

4) Adopting PLC control system, this forming machine offers high efficiency, stable quality, less procedures and materials, thus reducing the production cost.

5) Fluid drive, large driving moment and stable run.

Technical Data of ZHL-150 Spiral Filter Core Forming Machine:

| Item | Specification |

| Spiral filter core diameter | 35-150mm |

| Applicable material | Galvanized steel, stainless steel |

| Applicable material thickness | 0.25-0.7mm |

| Applicable material width | 50/60mm |

| Feeding speed | 0-35m/min |

| Main drive motor power | 3kW |

| Machine size | 1600×800×1240mm |

| Machine weight | About 800kg |

Photos of spiral filter cores can be made by this machine:

By adding an eccentric punching press to the production line, round hole perforated filter cores can be produced.

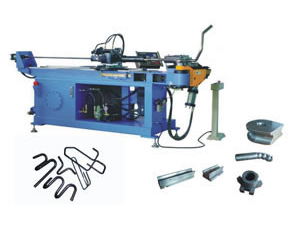

This is another filter core machine that produces expanded mesh filter cores.

| Item | Data |

| Suitable filter core diameter | Φ130-400mm |

| Suitable raw material thickness | 0.35-0.6mm |

| Suitable raw material width | 65mm |

| Expanded mesh width | 130mm |

| Production speed | 0-6m/min |

| Main motor power | 4kW |

| Cutting method | Non-stop round blade cutting, chipless and noiseless |

| Main machine dimension | 1700 x 1100 x 1500mm |

| Weight | About 1000kg |

Photo of ZHL-600 Spiral Filter Core Forming Machine

Premium quality roll forming machine, spiral duct forming machine, plasma cutting machine, welding machine and other forming machines are supplied in Haoshuo.

English

English Español

Español Русский

Русский Português

Português Français

Français العربية

العربية