- Home

- Products

- Transformer Making Machine

- Corrugated Tank Machine

Corrugated Tank Machine

Corrugated Tank (Fin) Forming Machine

This machine can automatically fabricate corrugated fins for transformer corrugated tanks.

I. Buildup of the line

1. Decoiler: mechanical expansion, passive, capacity 6T.

2. Hydraulic station: max. pressure 30MPa, max. flux 100L/min, pump motor 7.5kW;

main hydraulic components are from Taiwan.

3. Main forming unit: hydraulic driven, automatic forming

4. Shearing device: hydraulic driven to cut formed fins

5. Run-out table: manual, 3m long

6. PLC control system: PLC, inverter, touch screen, encoder, are Mitsubishi from Japan; electric components are Schneider brand, from joint venture in China.

II. Main technical data:

| Item | Specifications |

| Width of raw steel coil | 300-1500mm |

| Thickness of steel | 1-1.5mm |

| Height of fin | 100-400mm |

| Pitch between fins | 45-80mm |

| Space inside fin | 4-6mm |

| Forming speed | 3 fins per minute |

| Dimension | 5500×1600×2200mm |

Corrugated Tank Fin Welding Machine

This machine is special designed for welding fins of corrugated tanks. All mechanical equipment related to transformer also can be provided.

Main Technical Data

| Item | Specifications |

| Suitable fin size | Max. 1400×1400×500mm |

| Suitable fin thickness | 1-1.5mm |

| Suitable space inside fin | 4-6mm |

| Welding speed | Fin height of 100mm: 3 fins/min Fin height of 200mm: 2 fins/min (Depending on fin thickness) |

| Argon arc welding machine (TIG) | Two pieces, welding current 30-300A |

| Compressed air | 0.8MPa |

| Machine weight | About 4000kg |

| Dimension | About 3600×2000×2000mm |

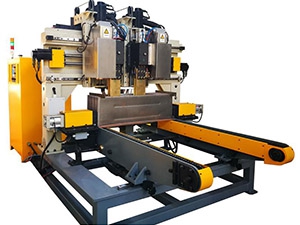

Transformer Corrugated Tank Fin Reinforcement Spot Welding Machine

This is one of our patented machines, designed in house for the best spot welding reinforcement on corrugated fin panels formed using a transformer corrugated tank fin production machine.

Two spot welding torches are driven by servo motors and PLC control. The height, position and stroke can be pre-set based on the fin panel height and width, and the welding process utilizes a resistance weld, quick welding speed, and a low noise level. Fin panel movement is driven by an inverter controlled motor, and the movement stroke can be preset based on the fin pitch.

Technical Data

| No. | Item | Data |

| 1 | Suitable fin width | 300-1300mm (can be customized) |

| 2 | Suitable fin height | 100-400mm |

| 3 | Suitable steel thickness | Max. 1.5 + 1.5mm |

| 4 | Input electric power | AC 380V, 3phase, 50Hz (can be specially ordered) |

| 5 | Welding transformer power | 100kVA |

| 6 | Rated primary welding current | 160A |

| 7 | Secondary no-load voltage | 7.2V |

| 8 | Load sustained rate | 50% |

| 9 | Pneumatic source | 0.4MPa |

| 10 | Cooling water flow | 30L/min, 0.2MPa |

| 11 | Total motor power | 8kW |

| 12 | Machine dimension | About 4500 x 2400 x 2300mm |

| 13 | Machine weight | About 3500kg |

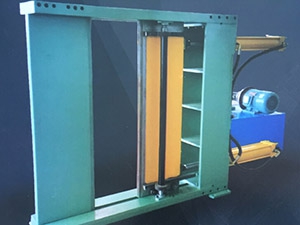

Transformer Corrugated Tank Fin Wall Bending Machine

This machine is specially designed to bend fin walls with several units into 90 degree angles.

Technical Data

| No. | Item | Data |

| 1 | Suitable material thickness | 1.0-1.6mm |

| 2 | Suitable fin height | 50-400mm |

| 3 | Suitable fin width | 300-1600mm |

| 4 | Distance between two units | More than 60mm |

| 5 | Hydraulic pump motor power | 2.2kW |

| 6 | Pump motor | SIEMENS from China |

| 7 | Electric components | SCHNEIDER from China |

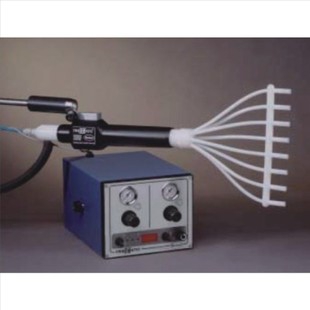

Powder Coating Line for Transformer Corrugated Tanks

We can design powder coating lines for transformer corrugated tanks based on customers’ requirements, and the automatic degree can be customized based on the customer’s budget. By using a Nordson special spraying gun system, the transformer corrugated fin tank is expertly coated.

English

English Español

Español Русский

Русский Português

Português Français

Français العربية

العربية