Description

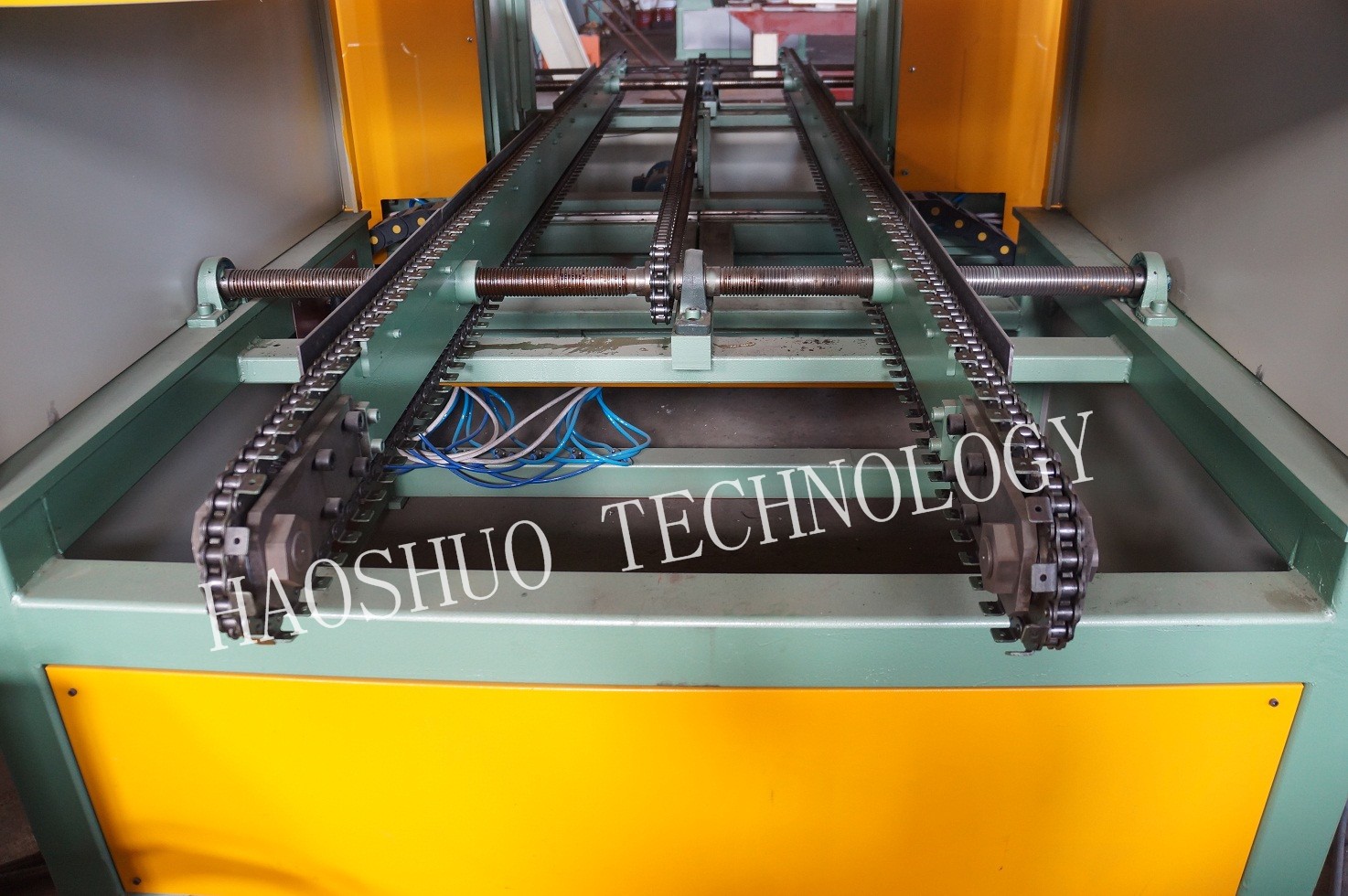

This corrugated fin welding machine is a specially used in transformer manufacturing industry. It adopts air cylinder to clamp the fins. Driven by DC speed motor and weld the fins, the welding gun can move from top to bottom through ball screw.

Features

1. Adopting argon arc welder automatic welding, the welding quality can be ensured.

2. You can also manual operate the corrugated fin welding machine easily.

3. The whole electric circuit is controlled by PLC system, so the machine can run in fully automation mode.

4. Transformer corrugated fin welder can work continuously due to the application of air cylinder feeding.

Maintenance and Packaging

1. This welding machine should obey the work instructions.

2. The welding electrode should be checked regularly.

3. Keep the machine clean.

4. This machine is suitable for seaworthy packing.

Parameters of Corrugated Fin Welding Machine

|

Machine type

|

W1300/1600 × 400

|

|

Fin Spec

|

Suitable material

|

Cold rolled steel

|

|

Steel thickness

|

1-1.5mm

|

|

Forming

|

Max. 1300mm (1600mm)

|

|

Fin

|

50 to 400mm

|

|

Pith distance

|

45 to 80mm

|

|

Fin gap

|

6 to 8mm

|

|

Motor for fin forwarding

|

1.1kW

|

|

Motor for adjusting

|

1.5kW

|

|

Motor for welding gun moving

|

Servo motor 400W × 2 sets

|

|

Welding machine

|

SanRex (Japan) TIG welder, 2 sets

|

|

PLC system

|

Schneider (China) brand

|

|

Touch screen

|

Schneider (China) brand

|

|

Machine dimension

|

4000 × 2000mm (L× W)

|

|

Gross weight

|

About 1500kg

|

|

Input voltage

|

380V, 50Hz

|