Properties

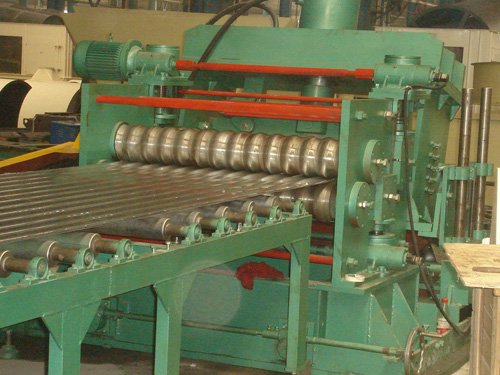

1. This thick corrugated panel roll forming line for steel silo adopts reasonable steel structure. It has the traits of large loading ability, stability and reliability; ,

2. This forming roller in China is designed by professional technical personnel. After heat treatment, the roller with high forming accuracy and long service life is coated by chrome plated.

3. The other parts of thick corrugated panel roll forming line for steel silo are all from the well-known brands. It can ensure the performance and quality of machine;

4. The operator can work without special training;

5. It can work with low noise and high efficiency.

Operation

1. Due to automatic PLC control, the operation is very simple. Thick corrugated panel roll forming line for steel silo can work automatically only though the import of the related production data, such as product number, length and punching size, etc.

2. If you need to adjust the roll forming machine, please be sure to stop the machine and then go on the relevant operation.

Maintenance and Packaging

1. This roll forming machine should be operated according to the work instructions.

2. Add the lubricating oil regularly on sprocket chain, bearing, and reducer.

3. Keep the forming roller clean.

4. This thick corrugated panel roll forming line for steel silo is suitable for container transportation by sea.

5. It is fixed with wire rope and block.

Parameters of Thick Corrugated Panel Roll Forming Line for Steel Silo

1. Suitable material: cold/hot rolled coil, galvanized steel coil, etc

2. Forming profiles: thickness 1.5-4.2mm

3. Max feeding coil width: 1250mm

4. Machine work speed: 4-6m/min

5. Total power: approx 180KW

6. Power supply: AC380V±10%, 50Hz, 3 phase

7. Whole line dimension: about 35M×4.5M (L×W)

8. Installation height: 4.5m

9. Total weight: approx. 70 tons (about three 40 containers for shipment)