Description:

Hot-dip galvanizing is the reaction of molten metal with an iron substrate to produce an alloy layer, thereby combining the substrate and the plating layer. Hot-dip galvanizing is to pickle iron and steel parts first. In order to remove iron oxide on the surface of iron and steel parts, after pickling, it is cleaned in an ammonium chloride or zinc chloride aqueous solution or a mixed solution of ammonium chloride and zinc chloride. And then sent to the hot-dip plating bath. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Galvanized steel coil products are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and other industries. Such as building roofs, highway guardrails, sheet metal processing, roof grilles, household appliance enclosures, ventilation ducts, chimneys, kitchen utensils, grain storage and transportation, frozen processing of meat and aquatic products, etc.

Specifications:

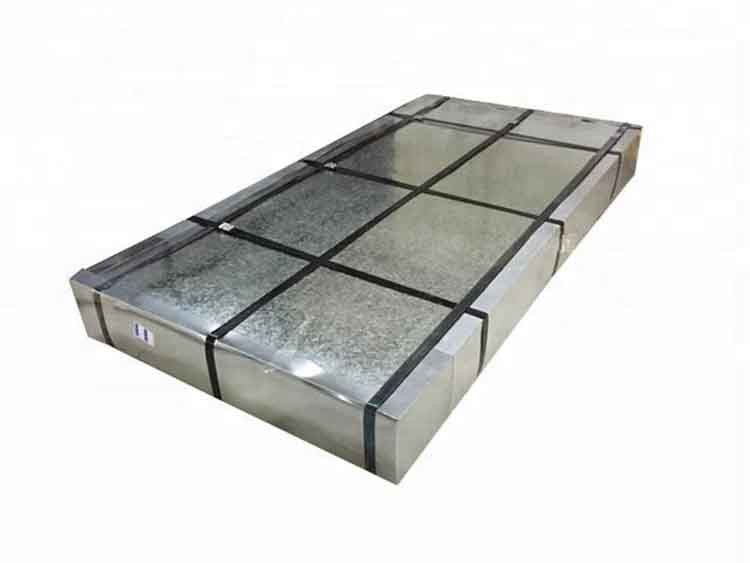

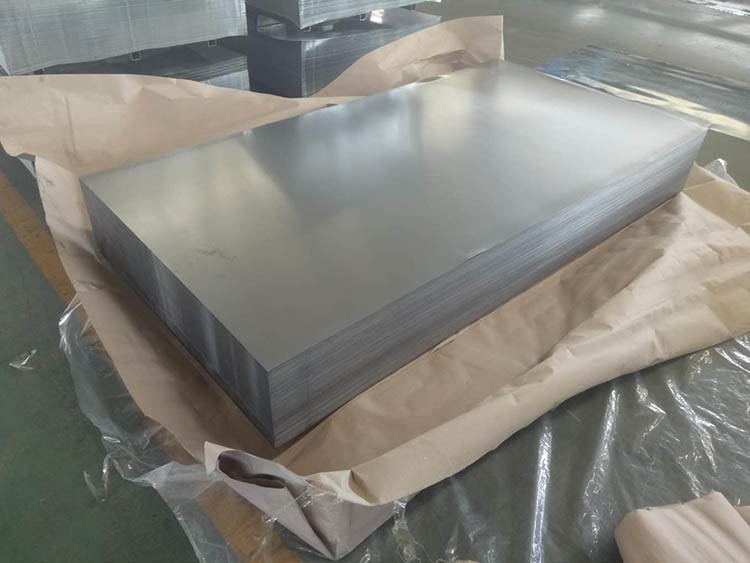

1)Product name: Galvanized steel, GI coil, zinc coated steel

2) Grade: SGHC, SGCC, DX51D, Q195, all according to the customer's request

3) Standard: JIS G3302 1998, ASTM A653M/A924M 2004, etc.

4) Thickness: from 0.12mm to 4.0mm, all available

5) Width: from 600mm to 1250mm, all available

6) Coil ID: 508mm/610mm

7) Coil weight: from 3-8MT, according to the customer's request

8) Zinc coating: 30g/m2-275g/m2

9) Spangle: big spangle, normal spangle, small spangle, non-spangle

10) Surface treatment: Chemical passivating, oils, passivating + oils

11)Technology: hot dipped galvanized