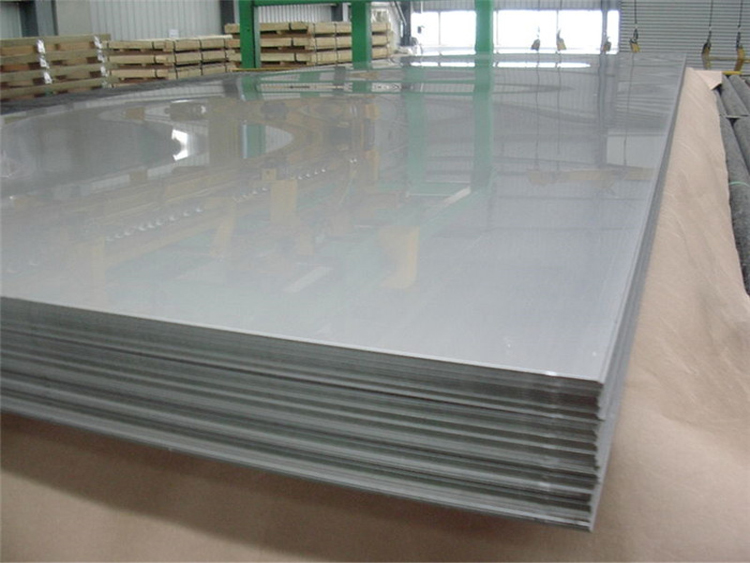

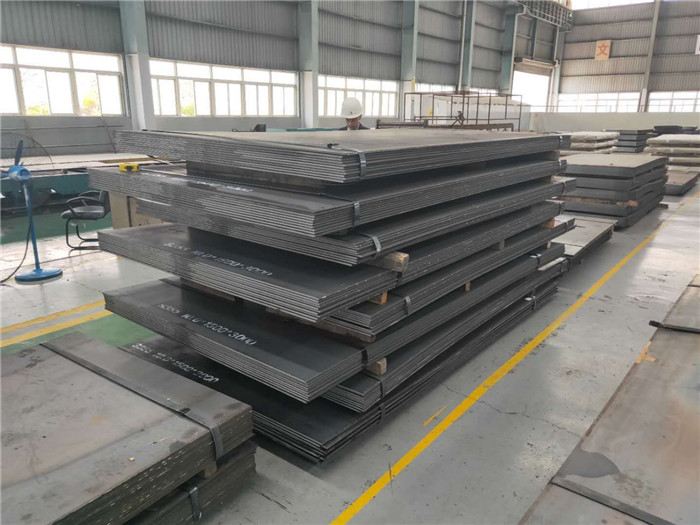

Cold Rolled Steel Coil & Sheet

1.Product name: cold rolled steel CRC

2.Application: Industrial Equipment, building materials and cars, etc.

3.Standard: AISI, ASTM, BS, DIN, GB, JIS

4.Grade: DC01, DC02, DC03, DC04, ST12, ST13, ST14, ST15, SPCC, SPCD, SPCE

5.Width: Coil: 600 -1250mm; Sheet: 600 – 1500mm

6.Thickness: 0.18-3.0mm

7.Coil ID: 508mm/610mm or as per customer's requirement

READ MORE