Description

Our company professionally offers EPS panel forming machine. Our EPS foaming sandwich panel enjoys beautiful appearance, bright color, and good overall effects. This machine integrates load-bearing, heat preserving, fireproofing, waterproofing into one unit. There is no need to do secondary fitting up. This machine has wide application, especially in building site temporary facilities, such as offices, warehouses, and enclosing walls, etc. It shows civilization construction in modern building sites. This equipment has obvious advantages, especially in rapid installation and utilization aspects, removable parts and material recycling and reusing index,

Besides, this machine can greatly reduce temporary facility costs in building sites, and it is an indispensable new light weight construction material.

The main components of this EPS panel forming machine are roll forming machine, liquid glue mixing and scraping device for foaming, one set of cutting device, one set of transferring rack, and electrical control device.

Properties

The EPS panel forming machine possesses advanced equipments, and unique production technology. And it is the leading equipment in domestic industry.

Operation and Points That Need Attention

The production sites should indicate off-limits place and operation place. When production is processing, people shouldn't go near the production site.

Maintenance and Lubrication

Users should regularly check lubrication motor, bearings, and conveyor devices.

Packaging and Transportation

This machine has to be covered by thin film, and it adopts sea shipping by container. And if no special requirement, this machine usually utilizes nude packaging, with cable wire and wooden block fastening it. All gadgets should be placed in accessory box.

Parameters

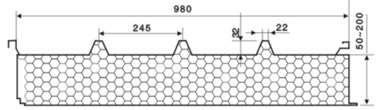

Usually we offer custom made panel at specific requirements of customers. And in the following, general panel types will be given.

Common use material and specification as following

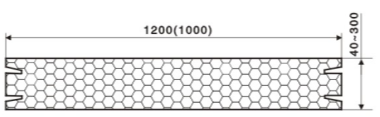

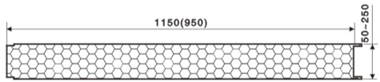

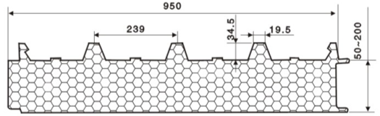

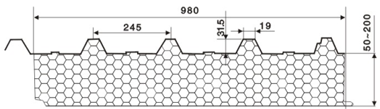

| Shape | Thickness (mm) | Color steel Width (mm) | Core thickness (mm) |

| A. Panel | 40-300 | 1200/1000 | 48-298 |

| B. H panel | 50-250 | 1200/1000 | 48-248 |

| C. Jack panel | 50-200 | 1200/1000 | 48-198 |

| D. Roof panel | 50-200 | 1200/1000 | 48-198 |

| E. Corrugate panel | 50-200 | 1200/1000 | 48-198 |